Khoren Sahagian

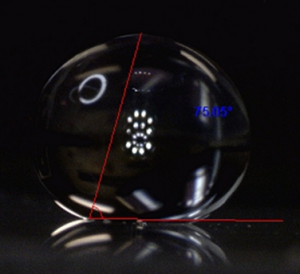

A proprietary PTS surface formulation is enabling SUPER omni-phobic surfaces on everything from machine tooling to porous media. This novel surface chemistry maximizes water contact angles in a manner that appears to almost defy gravity (see photograph below). The most impressive part of the process is that it is tunable to varying degrees of surface phobicity ranging from simple water, to oil, and finally even isopropyl alcohol! Unlike dip coating methods that exhaust exotic monomers such as POSS (fluorodecyl polyhedral oligomeric silsesquioxane) the PTS vacuum plasma process uses almost no monomer and requires no thermal or UV curing steps. This means true conformal coating of complex geometries with high yield and using a method that is superior in material and energy efficiency.

When deposited on machine molds and tooling the omni-phobic surface coating may act as a mold release, slip agent, & inhibit accumulation of debris. Improved serviceability increases manufacturing efficiency by extending machine component lifetime and reducing the costs & frequency of scheduled maintenance programs. Furthermore coating a thin film using plasma preserves micro-scale topography and ensures a permanent covalent bond with the substrate without the use of a primer or liquid etchant. Because the omni-phobic film is derived from a plasma vapor phase it may even deposit into the tortuously small pore sizes of contemporary filtration media. The coating is resistant to a wide range of temperature & chemistry. Recent investigation of the surface treatment also demonstrates bacteriostatic characteristics which may possibly be exploited as an anti-microbial surface or to improve yield in cell transfer labware.

Recommend

Write a comment