Dr. K. L. Mittal, Dr. Robert H. Lacombe

We interrupt the normal flow of this blog on “SURFACES: THE INVISIBLE UNIVERSE” to present a book review on a volume which should be of keen interest to all working in the field of atmospheric plasma technology. The volume in question is:

ATMOSPHERIC PRESSURE PLASMA TREATMENT OF POLYMERS: RELEVANCE TO ADHESION; Eds. Michael Thomas and K. L. Mittal (WILEY-Scrivener Publishing, 2013)

The volume contains 15 review articles ranging from surface modification with plasma printing to the deposition of nanosilica coatings on plasma activated polyethylene. Each article has been produced by leading experts in the respective topics and gives a truly authoritative examination of the subject matter under review. A quick look at the table of contents reveals the remarkable scope of this volume.

PART 1: FUNDAMENTAL ASPECTS

- Combinatorial Plasma-based Surface Modification by Means of Plasma Printing with Gas-carrying Plasma Stamps at Ambient Pressure; Alena Hinze, Andrew Marchesseault, Stephanus Büttgenbach, Michael Thomas and Claus-Peter Klages

- Treatment of Polymer Surfaces with Surface Dielectric Barrier Discharge Plasmas; Marcel Šimor and Yves Creyghton

- Selective Surface Modification of Polymeric Materials by Atmospheric-Pressure Plasmas: Selective Substitution Reactions on Polymer Surfaces by Different Plasmas; Norihiro Inagaki

- Permanence of Functional Groups at Polyolefin Surfaces Introduced by Dielectric Barrier Discharge Pretreatment in Presence of Aerosols; R. Mix, J. F. Friedrich and N. Inagaki

- Achieving Nano-scale Surface Structure on Wool Fabric by Atmospheric Pressure Plasma Treatment; C. W. Kan, W. Y. I Tsoi, C. W. M. Yuen, T. M. Choi and T. B. Tang

- Deposition of Nanosilica Coatings on Plasma Activated Polyethylene Films; D. D. Pappas, A. A. Bujanda, J. A. Orlicki, J. D. Demaree, J. K. Hirvonen, R. E. Jensen and S. H. McKnight

- Atmospheric Plasma Treatment of Polymers for Biomedical Applications; N. Gomathi, A. K. Chanda and S. Neogi

PART 2: ADHESION ENHANCEMENT

- Atmospheric Pressure Plasma Polymerization Surface Treatments by Dielectric Barrier Discharge for Enhanced Polymer-polymer and Metal-polymer Adhesion; Maryline Moreno-Couranjou, Nicolas D. Boscher, David Duday, Rémy Maurau, Elodie Lecoq and Patrick Choquet

- Adhesion Improvement by Nitrogen Functionalization of Polymers Using DBD-based Plasma Sources at Ambient Pressure; Michael Thomas, Marko Eichler, Kristina Lachmann, Jochen Borris, Alena Hinze and Klaus-Peter Klages

- Adhesion Improvement of Polypropylene through Aerosol Assisted Plasma Deposition at Atmospheric Pressure; Marorie Dubreuil, Erik Bongaers and Dirk Vangeneugden

- The Effect of Helium-Air, Helium-Water, Helium-Oxygen and Helium-Nitrogen Atmospheric Pressure Plasmas on the Adhesion Strength of Polyethylene; Victor Rodriguez-Santiago, Andres A. Bujanda, Kenneth E. Strawhecker and Daphne D. Pappas

- Atmospheric Plasma Surface Treatment of Styrene-Butadiene Rubber: Study of Adhesion Ageing Effects; Cátia A. Carreira, Ricardo M. Silva, Vera V. Pinto, Maria José Ferreira, Fernando Sousa, Fernando Silva and Carlos M. Pereira

- Atmospheric Plasma Treatment in Extrusion Coating: Part 1 Surface Wetting and LDPE Adhesion to Paper; Mikko Tuominen, J. Lavonen, H. Teisala, M. Stepien and J. Kuusipalo

- Atmospheric Plasma Treatment in Extrusion Coating: Part 2 Surface Modification of LDPE and PP Coated Papers; Mikko Tuominen, J. Lavonen, J. Lahti and J. Kuusipalo

- Achieving Enhanced Fracture Toughness of Adhesively Bonded Cured Composite Joint Systems Using Atmospheric Pressure Plasma Treatments; Amsarani Ramamoorthy, Joseph Mohan, Greg Byrne, Neal Murphy, Alojz Ivankoviv and Denis P. Dowling

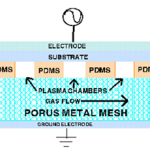

A cursory glance at the above list readily gives one the impression that the applications of the atmospheric plasma technique are limited solely by ones imagination. It is also clear that this short review will be able to cover only a small fraction of the material covered in this volume. Quite likely the most innovative paper in the collection is the one on “Combinatorial Plasma-based Surface Modification …” listed as number 1 above. This work attempts to take the process of plasma surface modification to a higher level through the use of “plasma stamps” which can be used to pattern a substrate with varying levels of plasma treatment in a single run. A schematic diagram of a plasma stamp is shown in figure (1). The substrate to be treated is patterned with an array of chambers using poly(dimethylsiloxane) PDMS as an insulator layer. The resulting array is sandwiched between a porus metal mesh and an electrode. The metal mesh in this case serves a dual purpose as a gas carrier and as an electrode.

The authors site a number of advantages of the plasma stamp configuration including:

- Due to the small size of the plasma chambers it is easy to supply nearly unlimited volumes of gas to the active micro-plasmas which is very useful when performing film depositions as opposed to simply performing a surface modification.

- Again due to the small cavity size the stamp can be rapidly filled using a small amount of gas. Thus the process is not only economical in the use of gas but the small chambers can be rapidly purged of unwanted oxygen which is a critical requirement when performing plasma nitrogenation treatments.

- The small cavity size also allows reaction products created in the cavities that are not deposited to be swept away efficiently in the gas stream. This is very useful in preventing fouling due to the redeposition of plasma polymers.

- Quite likely the most significant advantage of the plasma stamp technology is the fact that quite large arrays of the plasma micro-cavities can be created allowing for very efficient combinatorial studies of different plasma treatments on a single substrate in a single run. Thus one can easily imagine a 2 dimensional array where two different gas streams are independently introduced to the array from opposite sides of the inlet edge. The streams will combine continuously across the entire array of cavities giving a well defined gradient of gas composition over the entire array. Different cavities thereby receive different treatments depending on their location in the overall array. The results can then be inspected by any of a number of surface analysis methods such as Fourier Transform Infra Red spectroscopy (FTIR) or Xray Photoelectron Spectroscopy (XPS). Thus a large number of different surface treatments can be screened in a highly efficient manner.

Again the large scope of the volume does not allow us to comment on the other equally interesting articles. It should be clear, however, as mentioned above that the possibilities are limited only by the imagination.

Recommend

Write a comment