Khoren Sahagian

Contact angle and dyne inks are commonly accepted methods for probing surface energy. Surface energy is a good first indicator of a clean, bondable, or wettable surface.

For typical plastic and composite materials, the surface begins with low surface energy or a high water contact angle. Aqueous solutions and many adhesives have difficulty wetting onto materials with low surface energy.

Plasma processing incorporates the surface with reactive groups that promote wetting and adhesion. But not every material responds the same to every plasma treatment. With some materials, you have to find the correct plasma gas or plasma source to achieve the desired response. A contact angle or dyne ink will quickly show you if you have that response, or if you should try a different variable.

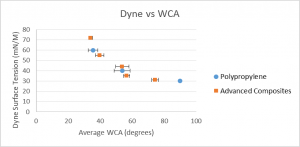

Brighton Technologies in Cincinnati, Ohio has created a graph that cross-correlates between a water contact angle (WCA) and dyne surface tension mN/m, which they have allowed us to reproduce here. This is helpful for those trying to replace their dyne inks, or those who wish to convert their contact angle data into an engineering unit.

We hope it’s helpful to you (click on the chart to expand it).

Recommend

Write a comment